Welcome

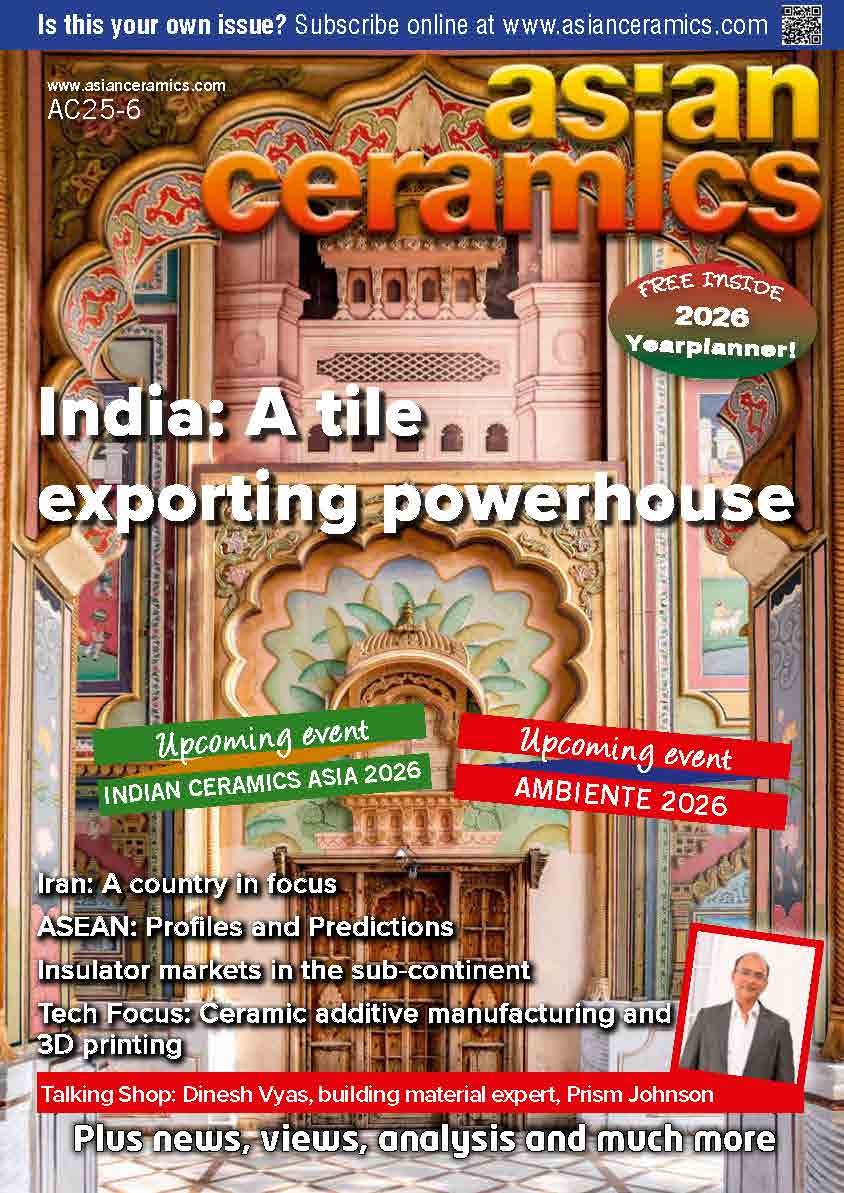

As we bring the year to a close, it is striking to reflect on how far the global ceramics industry has evolved and accelerated over the past 12 months. Across Asia and beyond, advances in manufacturing, technology adoption, sustainability and international trade have shaped a sector that is more dynamic and interconnected than ever. This edition highlights several of the year’s defining developments, examining the forces driving growth, the challenges facing major producers and the outlook for 2026.

India continues to reshape the global ceramic tile landscape at a remarkable pace. In little more than a decade, the country has risen to become one of the top two producers and exporters worldwide. At the centre of this rise is Morbi, now established as a global production hub whose scale and ambition have helped position India as a true tile exporting powerhouse. Yogender Singh Malik explores how capacity expansion, design innovation and sharper market orientation have enabled the industry to secure such a prominent international role.

Across Southeast Asia, the ASEAN ceramics sector is experiencing steady expansion, fuelled by active construction markets, rapid urbanisation and rising demand for high value ceramic products. Valued at around $8 billion in 2024, the region remains an important contributor to global supply. Yet, as Jahir Ahmed reports, manufacturers face intensifying competitive and cost pressures. Improving efficiency, adopting advanced technologies and strengthening regional integration are now essential for sustaining competitiveness across the bloc.

South Asia’s energy transition is also reshaping demand for ceramic products. The rapid growth of electrification, the development of new high voltage transmission networks and extensive grid upgrades are generating strong demand for ceramic insulators. Producers in India, Bangladesh and Pakistan are benefiting from major infrastructure programmes and rising electricity consumption. At the same time, the emergence of composite alternatives is encouraging ceramic manufacturers to innovate and reinforce the long-term value of ceramic-based solutions. Jahir Ahmed’s analysis outlines how the insulator industry is positioning itself amid these shifts.

In the Middle East and North Africa, Iran remains the region’s largest sanitaryware producer and its second largest consumer. Despite its solid industrial base, the sector continues to operate under the constraints of sanctions, inflation and regional uncertainty. Yogender Singh Malik examines how Iranian manufacturers are modernising facilities, improving product quality and preparing for potential export expansion while navigating complex political and economic conditions.

Innovation also features strongly in this edition’s Tech Focus, which explores the fast-developing field of ceramic additive manufacturing. As Rohan Gunasekera reports, advanced 3D printing technologies are moving quickly from specialist experimentation into high value industrial use. From medical implants and dental components to aerospace parts engineered for extreme performance, ceramic additive manufacturing is unlocking new design flexibility and technical capability. This emerging technology reflects the growing role of ceramics in advanced engineering.

We also present an exclusive Talking Shop interview with Prism Johnson Limited, one of India’s leading integrated building materials companies. Speaking with Asian Ceramics, Dinesh Vyas discusses the shifting dynamics of India’s construction and materials markets, evolving tile demand and the increasing importance of technology, sustainability and collaboration in driving the company’s innovation led strategy.

As 2025 draws to a close, we extend our warmest Merry Christmas and Season’s Greetings to all our readers. We also offer our sincere thanks to our readers, advertisers, contributors and friends of the publication. Your continued support and engagement have been essential to our progress and success.

Looking ahead to 2026, we are energised by the opportunities the new year will bring. To our existing advertisers, we hope you will continue to benefit from the reach and reputation that Asian Ceramics offers. For those considering joining us, now is an excellent time. Through Asian Ceramics, you gain access to an influential readership, authoritative insight and visibility at many of the world’s leading ceramics events. We look forward to supporting your growth in the global ceramics market.

Inside the current issue

See us at:

Check out a sample issue

Follow the link to download a whole sample issue for yourself and see what AC has to offer Read it nowAdvertise

Intuitive, bespoke, highly effective marketing campaigns

Editorial

Download our editorial features schedule today.

Year Planner

Map out your business year with our free to download calendar